CNC CODING GUIDE Website

Free NX 7.5 - NX 11 training book, self learning instruction

This is a complete course from the beginning to the making of your first sketch, model and finally a nice manufacturing with a ready-to-use CNC program

You going to accomplish both sketch, model and manufacturing

-12 dec -18. I'v started the process to correct the written language, bits and pieces of it are ugly thanks to auto translate

If you feel to pay any amount of money to me for the work with this use this link paypal link

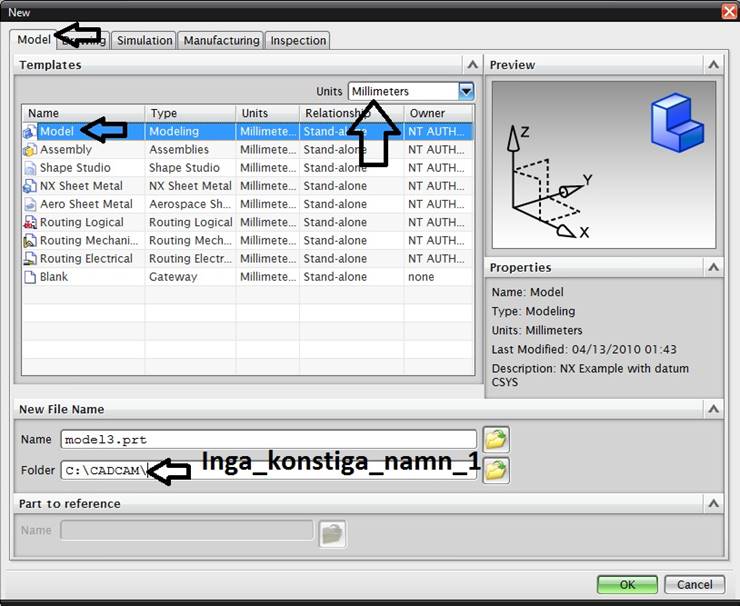

Create new file

We start all with

creating a model

Go to File >

New or use the icon with the same name.

choose the Model

tab, make sure Millimeter or Inch is selected for your desire

NX does not

handle file names, directory names, and more very well. It is important

to "format" the name correctly. Do not use Åäö and%-like characters.

Spaces shall be

represented by _ (underscore), the same applies if you mix numbers and letters.

The default directory

does not work good at all, creating a directory called CADCAM on your C drive

(c:/CADCAM) is the best choice

Text on pic = No funny names

Create

sketch

A solid is an

"air tight" form, we create the base of this form in 2-dimensional mode to create the air tight

volume on this later

To get the X, Y

and Z coordinates right from the start you have to follow a special pattern

when drawing in Sketch mode. Missed this now, it will give you problems towards the

end. Take note of the X,Y and Z-directions, really a p.i.t.a. to change later

Click the Sketch icon at the bottom (arrow) Make sure that Inferred option is active in plane method, Drag the pointer over the drawing area so the square lights up around the arrows, don't click! Select OK

Text on pic

= Hold the pointer over the sketch area, but do not click

Draw the

figure

All the details

we will make are based on squares and circles.

Turn up the CSYS

(as that 3 pointed Arrow shape is called) so that you have Y up and X to the right, Z

should point you straight to your nose

Choose to draw a square

Make sure to be

in the position with a square of 2 digits in the top left, dimensions are

entered and you have the option WIDHT Height or X and y, x and Y options keep

track of whether you are on the minus or the plus side of the figure. In W and

H mode, you must be in the correct quadrant with the pointer. See figure below

Type 0.0 to set

zero, then type the dimensions for the size of the square, right-click and choose

OK

After as we

previously clarified that everything is circles and squares is a negative

radius only part of a circle, select the Circle function and click on the inner

square corners. Make hole Ø to Ø20 (RADIUS 10). Click on the other three

corners without exiting the command

We need to trim

down the circle and a small part of the square so that it becomes a negative

radius.

Select Quick

Trim. Click the lines you want to remove.

Center-Marking or point

for hole-extrusion needed.In many cases a mark in the centre of the holes

with a + (point) in order to be able to select them when creating holes later. In this

case, it is not necessary for the centre points to be created by previous

drawing parts

Select Finish

Sketch to enter 3d mode

Create a

solid model

Select the Finish

Sketch to get over in the position where we can create a solid of our stretch.

The first

extrusion is the outer square. Select Extrude and double on one of the outer

lines, notice that connected curves must be selected. If the O-selected is

selected all the Infered is used.

Extrude in Minus

so that you as long as you can keep the drawn lines on the model top.

You can also pull

out the extrusion if you pull the purple arrow

Extrude up the

top as you extruded down the bottom part

The holes are

extruded with command Hole. Point in the box is the point to represent the hole

center.

Enter diameter 10

Depth limit can

be through Body, thus consistently or as in the box below, as Value. It does

not make the hole too long, as the hole that does not contain anything is

outside the piece

Create a

manufacturing

Select File >

New from the top menu. Select the Maufacturing tab and select General Setup. Make

sure the units are in millimeters or inch

The name of the manufacturing will be your Modelnamn + _ setup_1. Prt, folder shall be in accordance with the naming conventions of NX. Part To reference is your model.

You should be in

the operations Navigator mode and in Geometry View

We need to tell

the NX which your model you want to use and create a Blank, which will

represent your workpiece before milling before processing.

Double-click

Workpiece

Start by

selecting Specify Part

Blank Geometry

Choose as Auto Block, then the size represents the model's extreme values. You

can enlarge the Blank so that it provides processing on top and sides, but in

this case, we allow all values to be zero

In this General

Setup there are no default tools. So we must create them from new.

Click Create Tool

Type should be

mill_contour, Tool subtype containing different tool options, select Mill which

is a regular endmill

In Location

Select tool switches the location

Call the tool for

something you recognize, but remember how things get called according to NX.

Since I

deliberately made a mistake in this operation, we get an error message. I do

not reveal the error, it allows you to easily figure out yourself (NX 11 will handle spaces, 7.5 not at all)

We have to put a

number of values on the tool, diameter is most important.

Length is the

total length of the endmill, Flute Lenght is the length of the flutes, what is

shown yellow on the tool

Create

Operation

We use

Mill_Contoure as the Type

Operations

subtype contains lots of different processing options for processing, you can

use for example Z_level_profiling if you want to drive around the outer edge of

a detail.

We use

Cavity_mill quite often when it clear a number of different machinations.

Program 1234 does

not need to be changed

Tool, choose your

suitable tool

Geometry:

WORKPICE (and nothing else!)

Method adapts to

how you intend to process, options Finish and Rough

Names can be

changed to something you recognize, think of the NX and its naming rules.

Make sure the

WORKPIECE is your Geometry

Click Specify Cut Area

Select the area

you want to process. Sometimes you also have to choose the edges, but not now.

Go at the bottom

of the box and generate your choice, NX calculates the tool path now

If you change

something in the operation, you must regenerate

The generation creates the tool path, which includes quick runs and machinations, quick feed is red and blue, light blue is cuttin in the material. White and yellow represents approach and departure.

Verification

shows how the tool processes in the blank

But it also

creates the new model that will be after you have worked away, this used the

nice run then to know where the material is already gone and you do not have to

drive again. Then we have to choose to create a IPW (in process workpiece)

Create

Mill_finish

The operation is

basically the same as rough driving except that Method MILL_FINISH.

In this operation

the same as the rough run.

Select surface

and generate. Don't forget to save on ![]()

Create Drill operation

(Not in NX 11)

Select Drilling,

drill that you created and Method Drill_method, even here you can call the

operation for any name.

We skip the next

phase, which is the choice of diameter, we have gone through in the choice of

Mill and it looks alike here

In drilling we

have 3 choses.

Select holes can

be done by selecting > All holes On Face and selecting Top surface. If you

have more different large holes you can delimit the diameters before clicking

the surface

Specify Top

Surface selection is also Top surface, but it should be chosen as plane

The bottom

surface choose either the plane and the bottom surface or the drill depth with

ZC Constant, this does not require any click on surfaces

Generate the

drilling and study the tool path. Check carefully that the drilling really goes

down the hole, it does not do it, you have done something wrong in your model

or tool choise.

Red path

represents the coarse feed (G00) light blue corresponds to the working feed

(G01), when the colors are mixed, it is both types, in this case G01 down the

hole and G00 up out of the hole

Now all share

ready, it's time to verify the entire run as a package.

Select Workpiece

in Operation Navigator on the left, right-click, select Toolpath > Verify

Would! be

replaced with a stop sign, right click on the Workpiece and select Generate in

the menu, OK on all questions

Post Process

Now everything

should be adapted for a CNC machine.

Stand on the

Workpiece, click the post Process, either on the icon menu or with right

Select

Mill_3_Axis as the post processor (or the assigned to you)

In the File Name

box you should have the names right, otherwise this does not work at all, you

can not post if you have not followed the rules of name making.

Also choose

millimeters in the units as when needed, in this post, the Americans have poked

in both inchs and feet in NX, we don't want to use that if we are metric guys, our parts become 25.4 times smaller

.

You get the code

in the format we ordered, it is almost ready.

You need to

change some things, including the tool change rows that have the introduction: 0030 and

so on, this is necessary to do before we even try to bring anything to the

machine.

The one with good

memory knows that the sign:(serial file transfer between computer and machine, : is the program name) Indicates the program name that the machine will

assume, so you have 5 tool changes, the machine divides your program into 6

parts, completely unusable in other words

Threading

with Tap

Create a tap in

the Create Tool as usual, Diameter, Pitch and save this.

Select Create

operation, drilling and tapping operation

Select holes

according to drilling on Cycle – Standard thread

-Select OK at

Number of Sets

-click Depth,

select Bottom Surface or Model Depth for continuous threading. You can also set

the depth with the option Tool Tip Depth, then you get to enter the thread

length

-OK, OK and

generate

Threading

with Thread mill

Thread milling

works both with thread made in solid and with a straight hole, but unlike lathe

threading, the cutter operation does not inherit the properties from solid

thread.

-Create tools

-Create Operation

– Mill Planar-Thread Milling

-Specify Hole or

Boss button

Change From And

Pitch to Specify, mark the mantle area in the hole

Form shall be

Metric

Pitch is your

ascent (which is the same here and on the tool)

-Threading drill

Size same as thread inner diameter or drill diameter

-Depth must

correspond to thread depth

Also

-Major Diameter

(thread YD)

-Minor diameter

(drill Diameter again) (Dia-Pitch)

-Lenght Same as

thread length

Identification

of feed types

In order to be

able to identify what the processing does after generation, among other things

to find faults, all feed types have a pre-selected color, for example where

tools cut into materials become the tools light blue, quick feed becomes another another color depending on departure or approach.

The table below

shows the appropriate types.